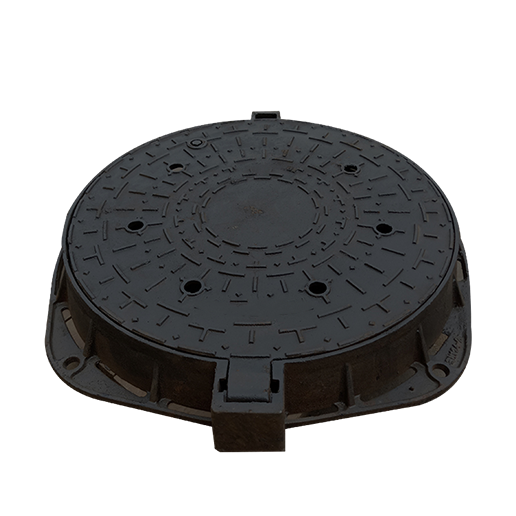

Will ductile iron manhole covers rust?

1. Will the ductile iron manhole cover be corroded?

On the road, you often see ductile iron manhole covers, and you will find that some manhole covers are corroded. Although it is a normal situation caused by long-term use, it will still affect the service life of nodular cast iron manhole covers. The root cause is that it has been in the outdoor environment for a long time and is often crushed by cars and hanging objects. If the manhole cover is found to be corroded, it must be cleaned in time.

2. The main reason for the rusting of ductile iron manhole covers

The main reasons for the rust of ductile iron manhole covers can be analyzed from two aspects: the manhole cover itself and the external environment.

1. Elements of manhole cover itself:

One is that the anti-corrosion processing technology is not done well, causing the manhole cover to directly contact with the outside gas moisture, resulting in corrosion. The second is mainly because the manhole cover has not been subjected to aging treatment, and the alloy components cannot be dissolved in the conventional method, resulting in slightly lower alloy elements in the base material and weaker corrosion resistance, making the manhole cover easily corroded.

2. External factors:

(1) During transportation, nodular cast iron manhole covers will inevitably experience friction and collision, which will cause damage to the surface layer. If exposed to the air for a long time, it will rust;

(2) Ductile iron manhole covers are generally used outside, and the chloride ion content contains acid salt, sweat scale, sea surface, etc. If there is chloride ion content, its etching rate is much faster than that of ordinary positive ions;

(3) Erosion caused by intergranular corrosion of nodular cast iron manhole covers, without titanium and niobium substances, will lead to intergranular corrosion;

(4) It is normal for ductile iron manhole covers to oxidize in the air outside.

3. Countermeasures against rusting of ductile iron manhole covers

1. Gushing anti-rust treatment

The compressed gas is processed through the oil-water separator, so that the wear-resistant material is sprayed out at high speed through the nozzle. Generally, the pressure of the compressed gas is 4~0.6MPa. The high-speed wear-resistant material with high pressure is used to produce friction and friction with the nodular cast iron manhole cover. Impact resistance, for this reason remove air oxidation and rust on the surface. This technology does not require a special location, it is easy to spray, has no dead angle, and the anti-rust treatment is cost-effective. A certain degree of roughness is pretreated for the surface of the manhole cover, which is beneficial to the adhesion of the coating.

2. Propellant anti-rust treatment

According to the rapidly rotating impeller blades of the shot blasting machine, the wear-resistant materials are scattered and sprayed onto the surface of the ductile iron manhole cover, and the wear-resistant materials fly out at lightning speed, impacting and rubbing against the surface of the ductile iron manhole cover, so as to remove the ductile iron manhole cover Corrosion and oxidation of manhole covers. This method has high working efficiency, high cost-effective antirust treatment, and can also obtain a certain surface roughness in ductile iron manhole covers, which is beneficial to coating adhesion, and has low labor intensity and is not easy to damage the environment. Therefore, many manufacturers will choose to use it first. this method.

Generally speaking, will the ductile iron manhole cover rust? I have explained it for everyone, and answered the reasons and solutions for the rusting of the ductile iron manhole cover. I hope it can help everyone!