#Flangeis a connection and sealing parts. If there is a quality problem in the production process, there will be leakage, causing economic losses, environmental damage and even safety accidents, so the welding and production of #flange is very important.

At present, there are two main production processes for #flanges: forging and casting. Let's look at these two major production processes and see how they differ.

The forging #flange is hammered numerous times with the forging press, so that the internal structure of the steel becomes tight, enhancing the mechanical properties and the strength. #Forged flange is mainly suitable for high pressure pipeline

First, the cylindrical billet is cut to a certain size, heated to a certain temperature to make it thermoplastic, and then the billet is continuously knocked on the cold heading machine to make the inside of the billet more dense, and the mechanical properties are better than the original billet.

The round hole above the #flange is washed out on the blank with a punching machine, and the blank #flange after forming is put into the electric furnace for heat treatment to increase the strength of the #flange. Finally, the blank #flange is cut and polished to become a usable #flange.

#Casting flanges have the characteristics of low manufacturing cost and high efficiency, and can be manufactured with complex shapes. #Casting flanges are mainly suitable for low pressure pipelines.

#Casting flange is also a commonly used manufacturing process, the metal is melted into liquid molten steel, then poured into the preheated constant temperature metal mold, forming the shape of the #flange, with the natural cooling of the casting for a period of time, and then quickly cooled and removed with cooling water, which can also increase the strength of the #flange. The product will finally be adopted by polished rust treatment.

The #flange, as a very small part in scale, is insignificant in the entire product, pipeline or machinery, but it plays a very important role. With the development of #flange materials and technology in the future, the whole joint connection process can be ensured to be more accurate and firm, improving the safety and reliability of use.

Usage of #flanges

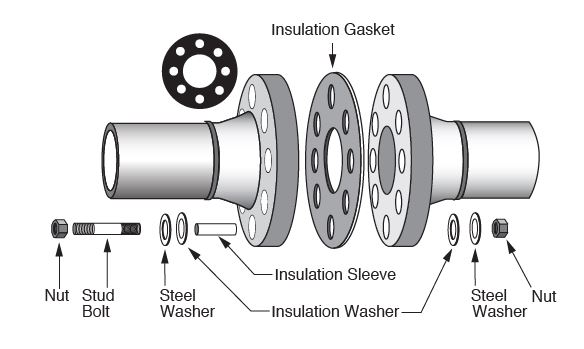

#Flanges are used in pairs. Threaded connection #flanges can be used for low-pressure pipes, and welded #flanges can be used for pressures above 4 kg. A gasket is usually added between the two #flanges and then fastened with bolts. The #flange thickness is different for different pressures, and the bolts used are also different.

#Valueup Group operates with strict product quality standards, we adhere to the principle of "quality is the life of the enterprise". At Valueup, we never expect any one-time business. We esteem to establish and maintain long-term cooperation with our clients for mutual benefits.

Warmly welcome friends from all over the world to visit our company for business.